Polymer Concepts Technologies designs, engineers and manufactures state-of-the-art application-specific sealing solutions and high-performance polymer and fluoropolymer components. We provide solutions ranging from vacuum to 50ksi and temperatures from cryogenic to 650F. We have materials and spring energizers which can withstand a corrosive media environment. We have a Total Quality Management System (AS9100D & ISO9001:2015) ensuring an industry-leading solution every time.

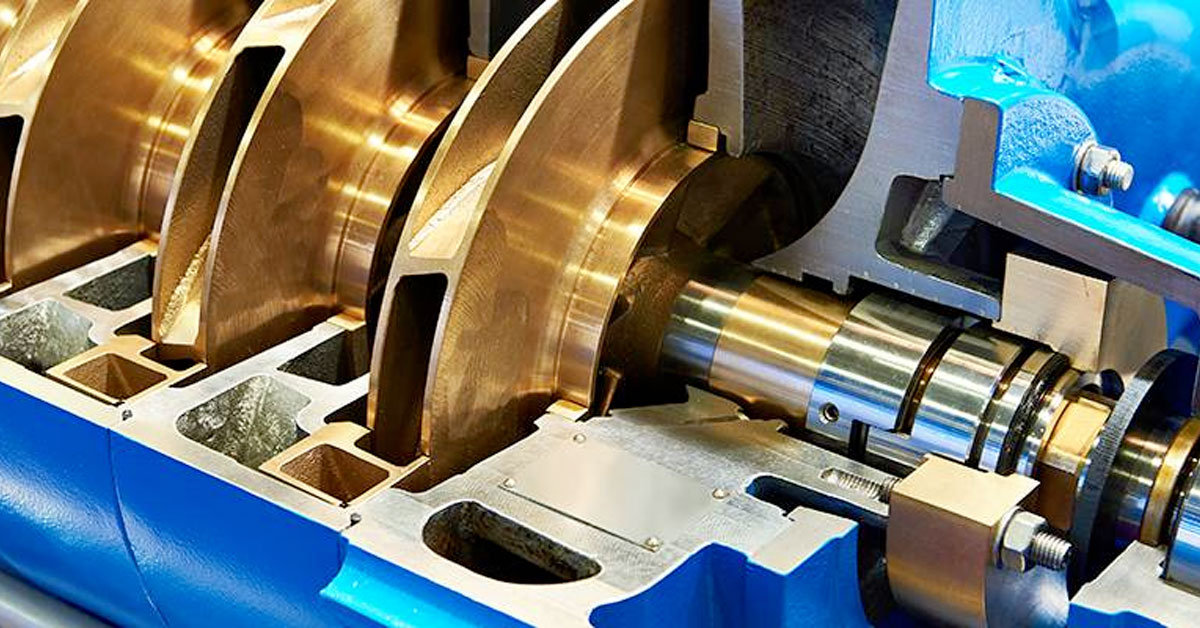

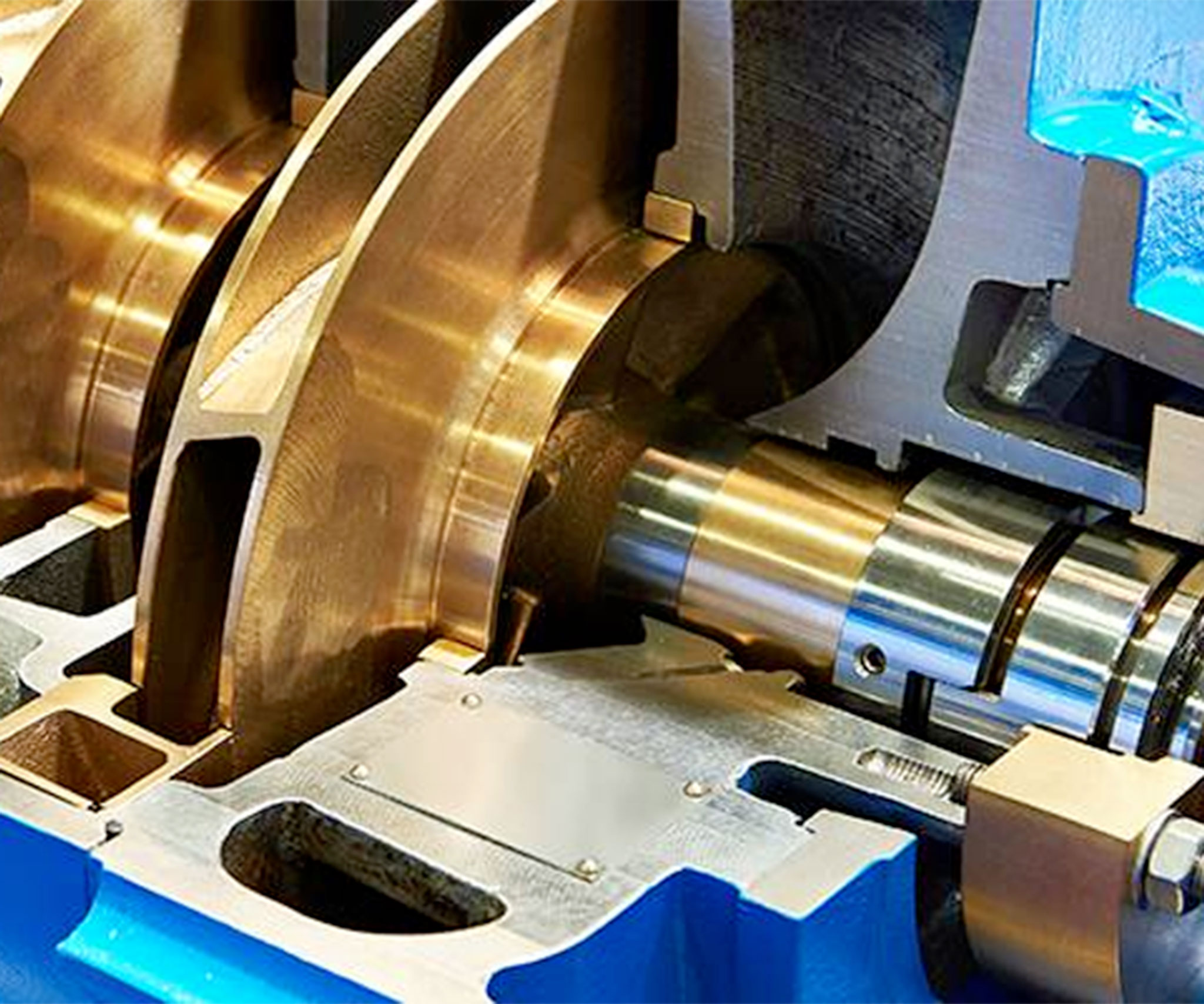

Rotating Equipment Sealing Applications

Pumps – API and Industrial

Mixing Equipment and Blenders

Rotary Swivels and Joints

Polymer Concepts’ Rotating Equipment Seal Advantages

Maintenance-Free Solutions

Low Friction and Wear

High Pressure Sealing

Lightweight Components

Excellent Chemical Resistances

High/Low Temperature Range

Seal & Component Design Services for Rotating Equipment

Engineered Designs

Is your current sealing solution not cutting it? Our in-house design team can help you develop one that will fit all of your operating requirements.

Seal Failure Analysis

Is your sealing solution not working or failing early? We can help with that using our in-house seal failure analysis team.

Prototype Lead Time

Our facility is equipped to quickly bring your designs to prototype fruition. We offer design services in a two to three business day window. Working prototypes in four weeks or less, and order to production within 30 business days.

Hardware Consulting

Are you working with standard or custom groove sizes in your hardware? We have the experience to help you in your lead-in sizes, chamfer/filet radius sizing, and installation tool design.

Reverse Engineering

Is your sealing solution out of stock or obsolete? We offer in-house reverse engineering and manufacturing services.

Ready to Place a Rotating Equipment Seal Design Request?

THE INDUSTRY-LEADING ENGINEERED SEAL MANUFACTURER

Polymer Concepts Technologies designs, engineers and manufactures state-of-the-art application-specific sealing solutions and high-performance polymer and fluoropolymer components. We take a collaborative technical approach with our customers and incorporate flexible designs, a vast material portfolio, and experienced manufacturing methodology to tackle the challenges of the most difficult applications. Our in-depth engineering experience, understanding of material characteristics, flexible service, rapid prototyping, and strong Total Quality Management System (AS9100D & ISO9001:2015) ensure an industry-leading solution every time.