Our Seal Products

Spring Energized Seals and PTFE Components, Engineered to Your Requirements

By working closely with our partners, we design, engineer, and manufacture custom solutions for the most performance-critical applications. Our products are exposed to extreme conditions of cryogenic service, high pressure/temperature environments, and areas where chemical compatibility is a necessity.

For example, applications in cryogenic delivery systems for spacecraft propulsion, aerospace engines and structures, oilfield tools and equipment, high speed medical, and rigorous specialized industrial rely on our products. We supply clean room-certified products from high purity materials manufactured to ISO9001:2015 and AS9100 QA standards.

Our focus is on sustaining mobility, meeting safety requirements, and protecting our environment. We also offer a collaborative approach to every sealing solution which is custom-designed, engineered, and manufactured to exceed the requirements of the application.

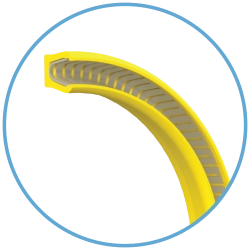

100 SERIES:

ADVANCED HELICAL SPRING SEALS (AHS)

The 100 Series seal design produces an evenly distributed load across each individual band. Polymer Concepts' manufacturing maintains minimal gaps between coils. This tight spacing provides continuous load, reducing potential leak paths. This tight spacing, combined with high unit load, makes this series well suited for vacuum and cryogenic applications.

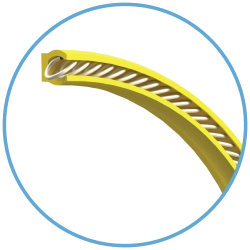

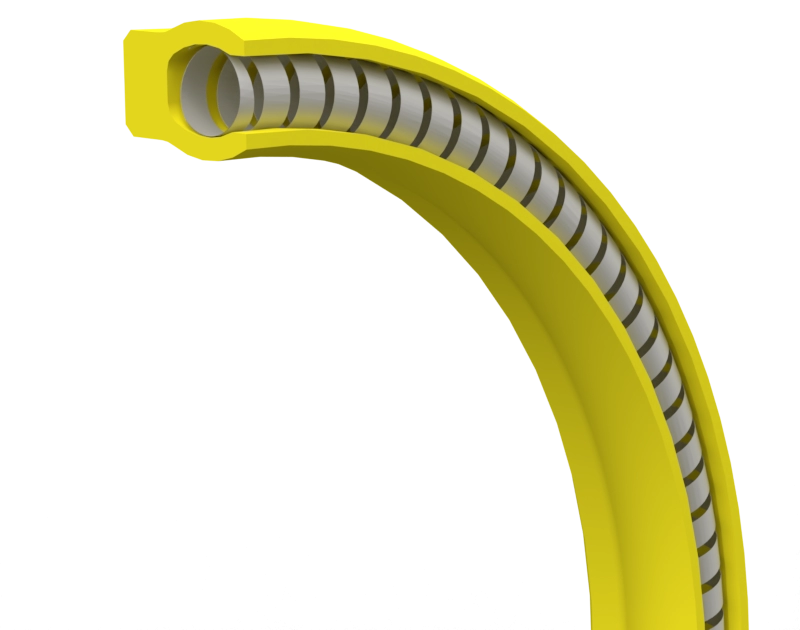

200 SERIES:

ADVANCED V-SPRING SEALS (AVS)

The 200 Series AVS seal produces much less friction compared to the 100 Series while being consistent with positive sealing at both low and high pressures.

The long beam leg design puts the spring load at the leading edge of the seal which allows the seal to act as a scraper or excluder seal. The 200 Series AVS seals can be supplied with an FDA approved grade of RTV silicone-filled into the spring cavity, allowing the seal to be used in food processing and clean-in-place applications.

The 200 Series AVS seals are available in all sizes to fit Industrial, Aerospace, and Military glands. Larger cross-sections up to 1/2” are also available.

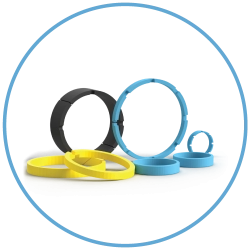

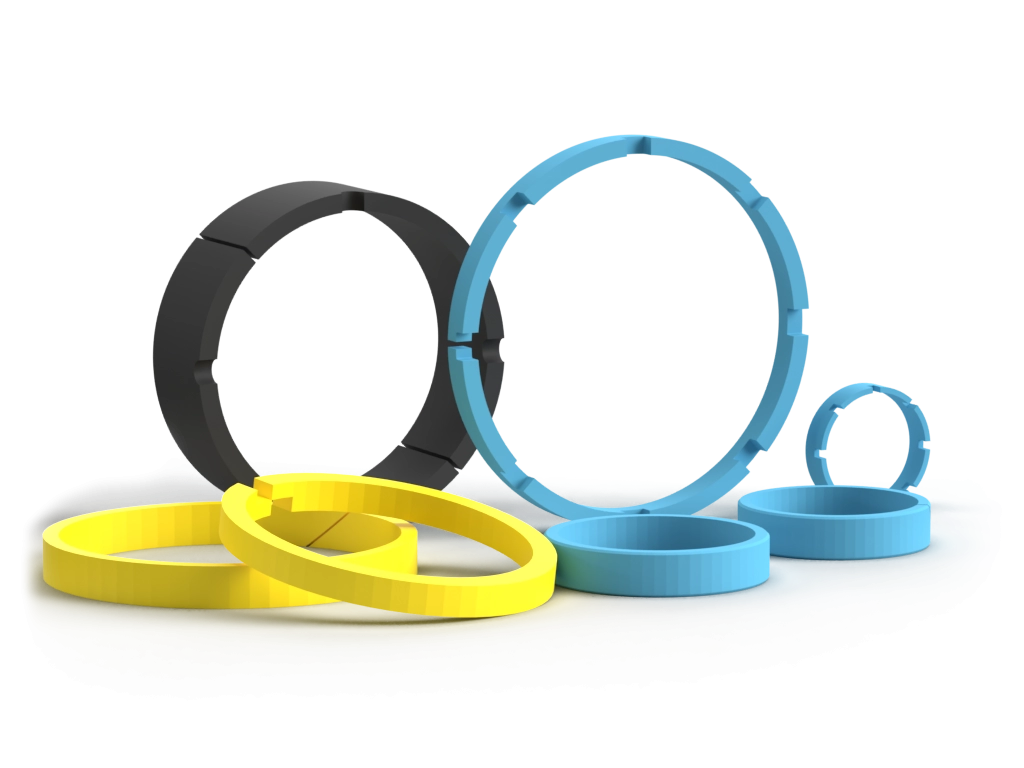

400 SERIES:

PRECISION MACHINED PLASTIC COMPONENTS

The 400 Series ‘Precision Machined Plastic Components’ include Adapter Rings, Bearings, Guide Rings, Skived-Cut/Z-Cut Piston Rings, and other intricate machined plastic parts that are used for a variety of customers in nearly every industry including Aerospace, Industrial, Instrumentation, Medical, Oil and Gas, and Semiconductor.

500 SERIES:

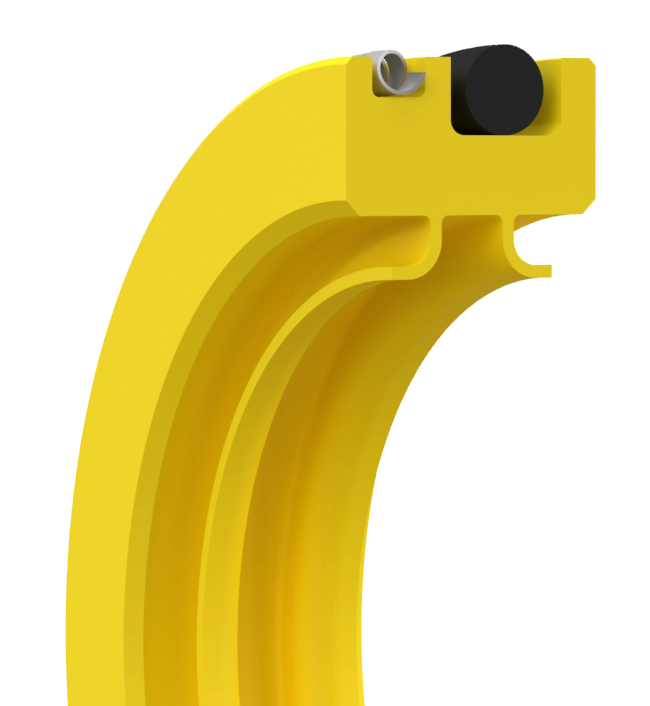

ADVANCED PTFE ROTARY LIP SEALS

Our 500 Series Advanced PTFE Rotary Lip Seal was developed to significantly improve the performance of elastomeric lip seals with high surface speeds, extreme temperatures, high operating pressure, and caustic environments.

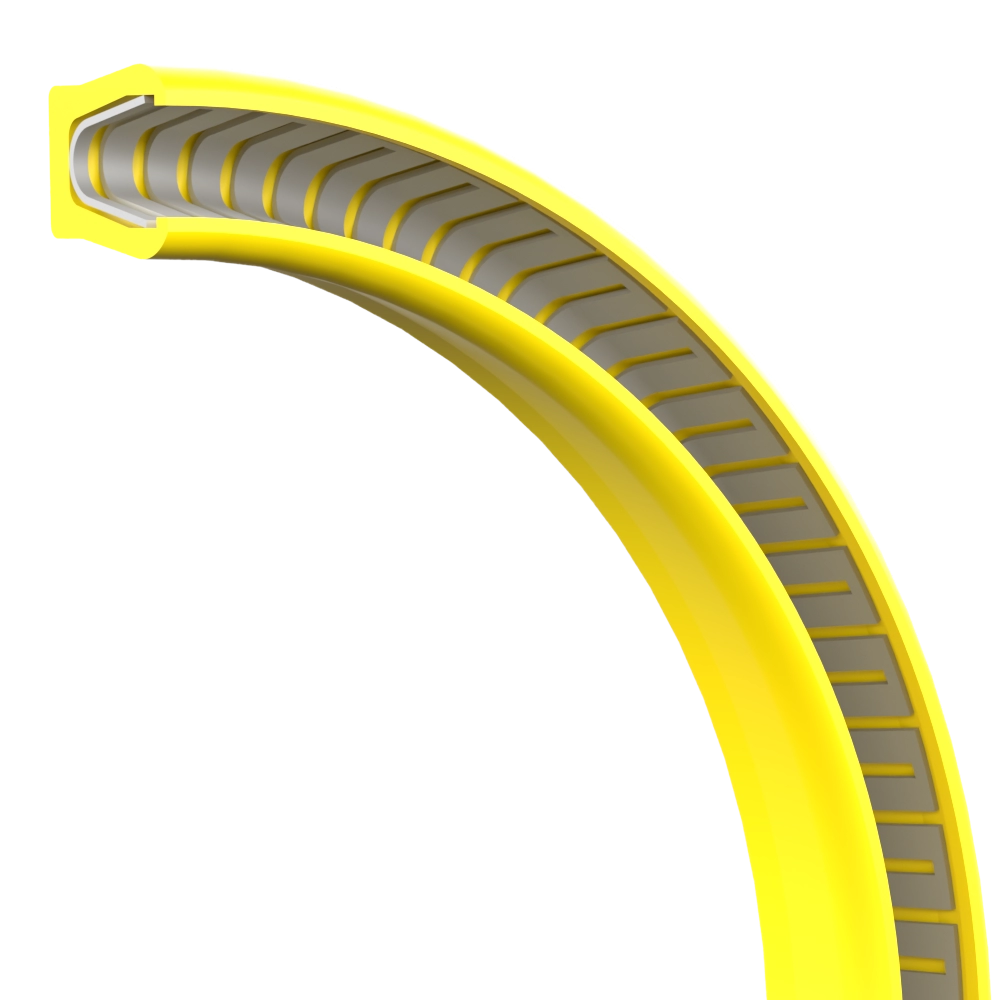

600 SERIES:

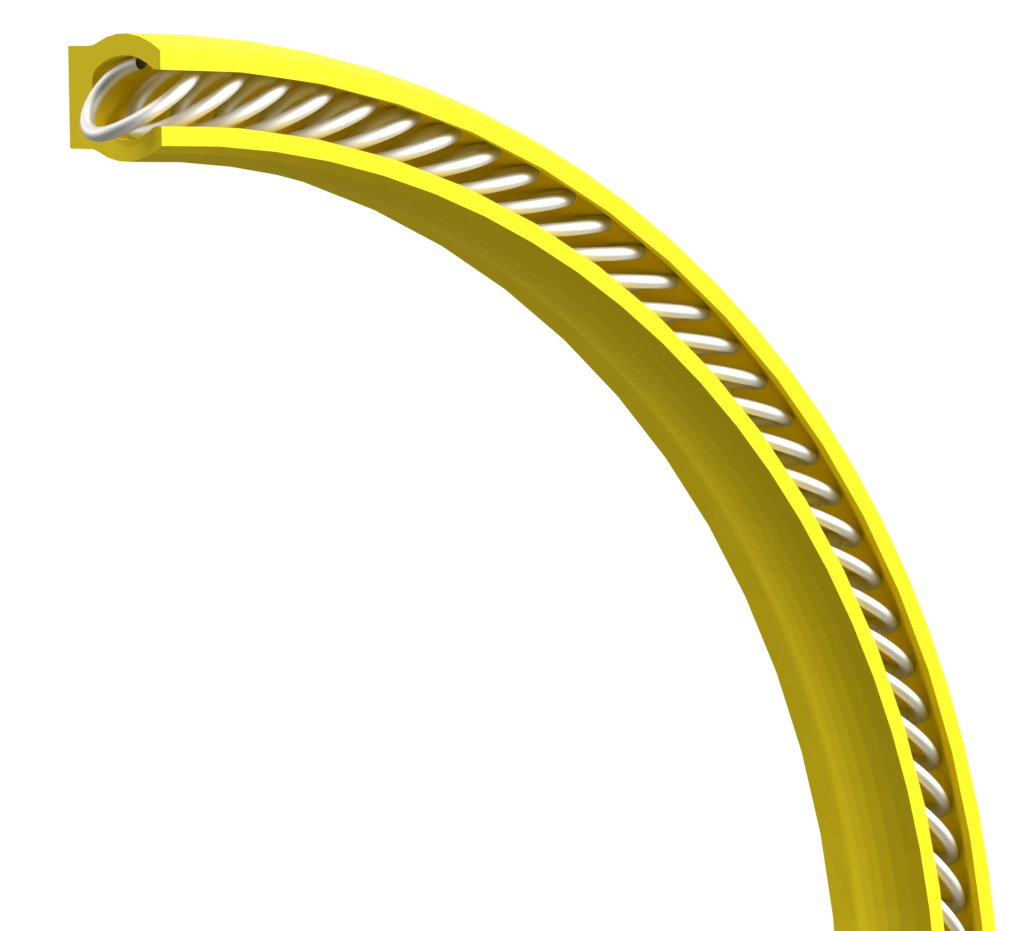

ADVANCED SLANT COIL SPRING SEALS (ACS)

Unlike any other types of springs, Advanced Slant Coil Springs produce near constant spring force over a wide range of working deflection and provide outstanding stress properties and fatigue life.

Advanced Slant Coil Springs have tremendous advantages in seal applications where they:

- Compensates for large run-out and wide gland tolerances

- Produces low friction and constant sealing force

- Provides high performance and extended seal life

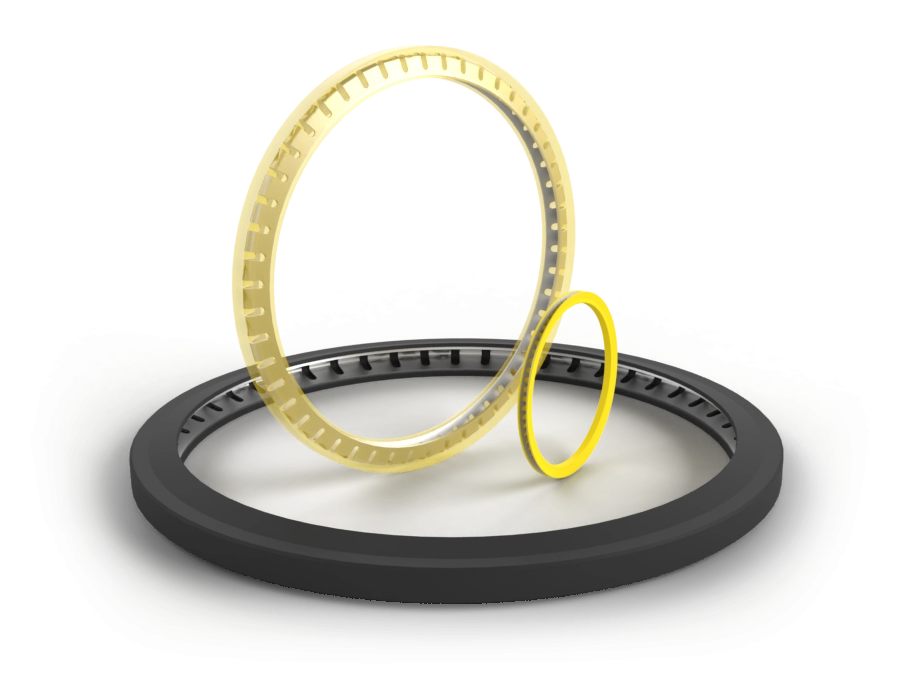

800 SERIES:

ADVANCED FULL CONTACT SPRING SEALS (AFS)

Polymer Concepts’ 800 Series Advanced Full Contact Spring Face Seal employs an extremely high load with continuous spring contact along the entire sealing lips.

This Face Seal was developed to provide exceptional performance for extreme static sealing conditions such as cryogenic fluids, ultra-high vacuum, and positive sealing of helium and other thin gases at low pressure.