NOMINAL FRICTION AND SEALING IN DYNAMIC APPLICATIONS

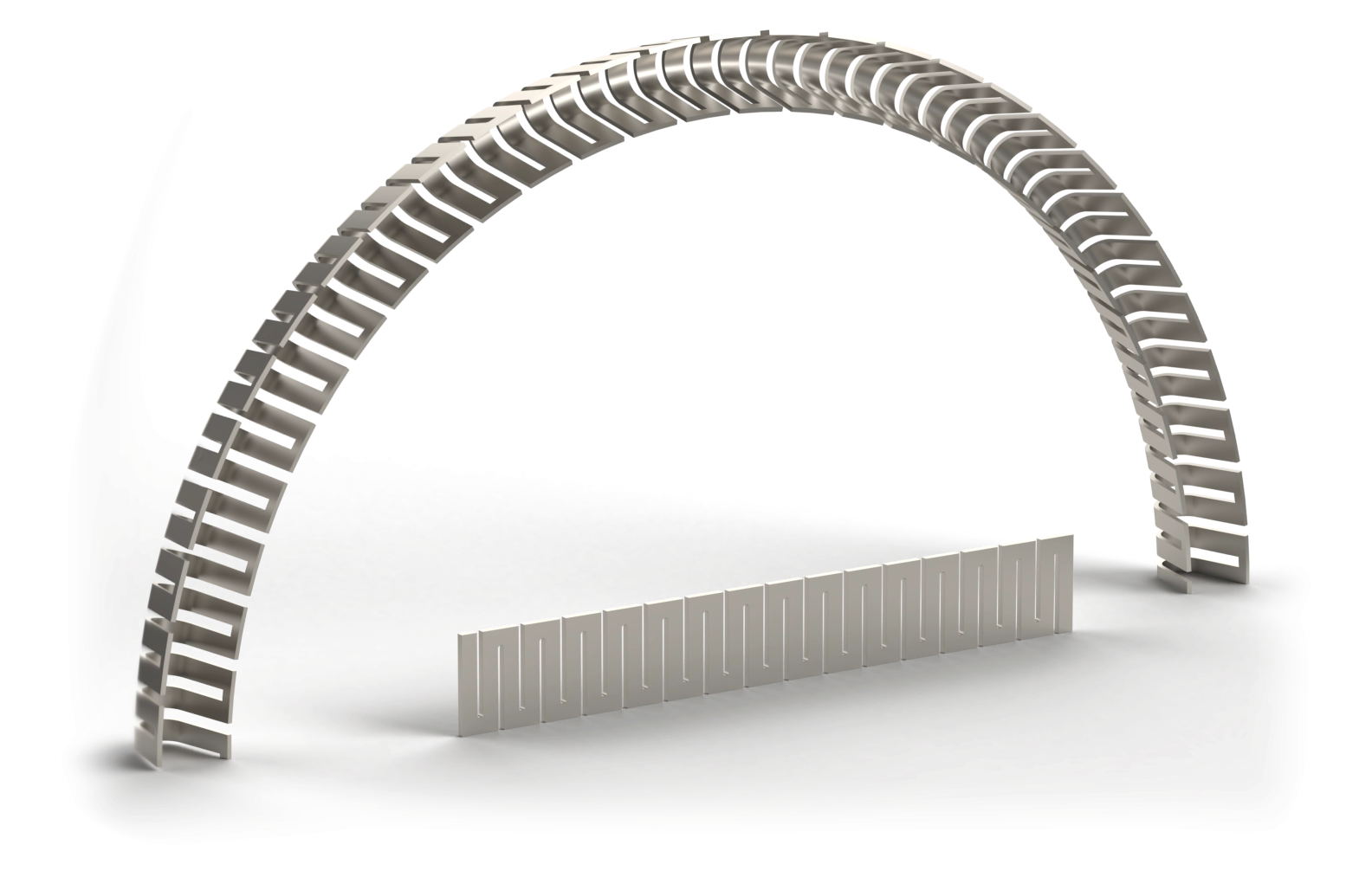

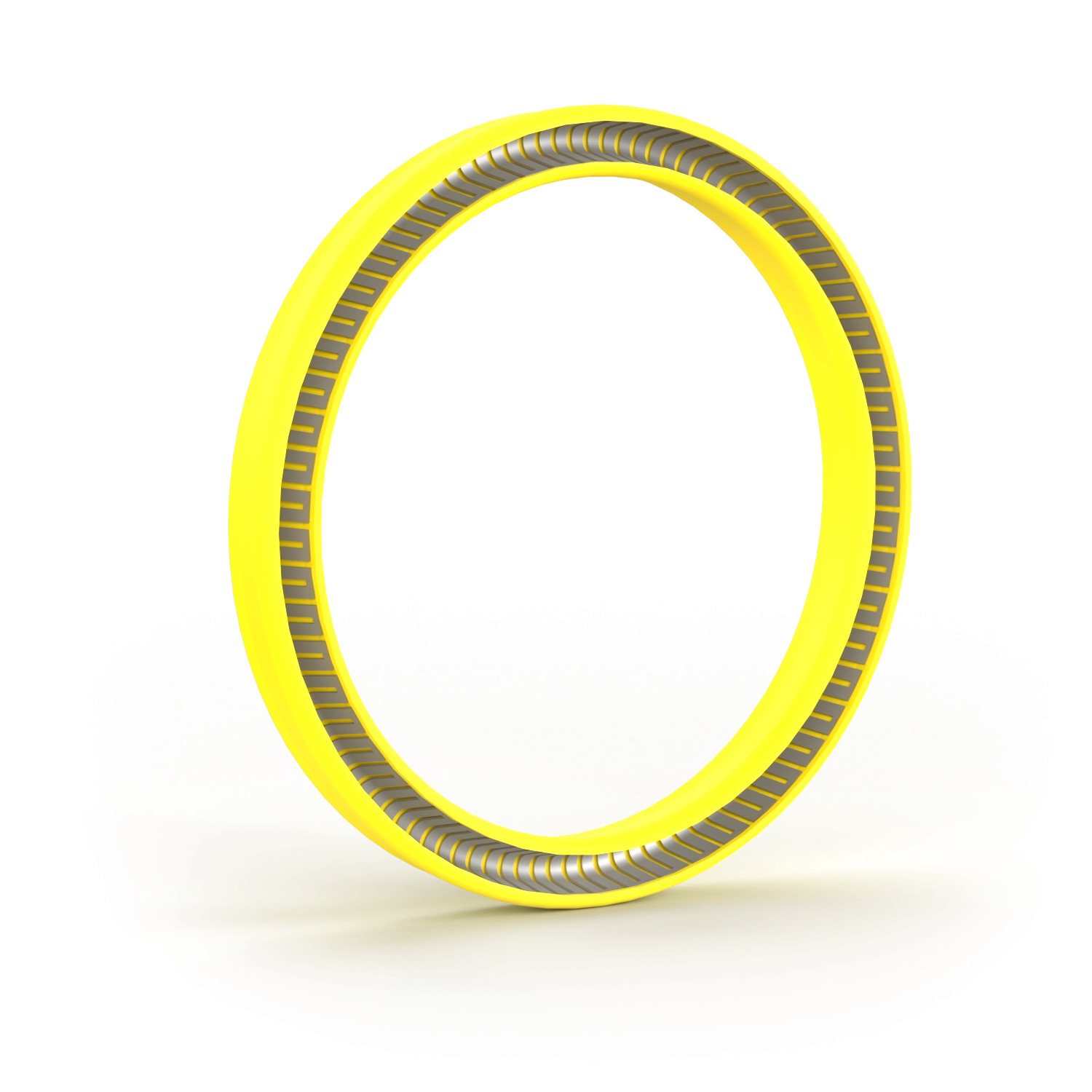

ADVANCED V-SPRING SEALS (AVS) DESIGNS:

Features:

- Provides moderate spring force versus deflection

- Various spring loads to meet friction and sealing requirements

- Cross-sections available are 1/16in up to 1/2in

- Available to fit in all Industrial, Aerospace, and Military gland sizes, with custom sizes range from .125” to 48” diameters

- Peek V-spring is available for non-metallic applications

- Springs are available in 17-7 SS, 301 SS, 304 SS, 316 SS, and NACE compliant Elgiloy®

Benefits:

- Permits dynamic runout and wide gland tolerances

- Provides low friction and optimum sealing

- Excellent in rotary and reciprocating motion

- Provides excellent scraping/wiping action for sealing abrasive and viscous media with skived lip design

- Provides PEEK V-spring for zero-emission of ions

- Allows for low clamping force

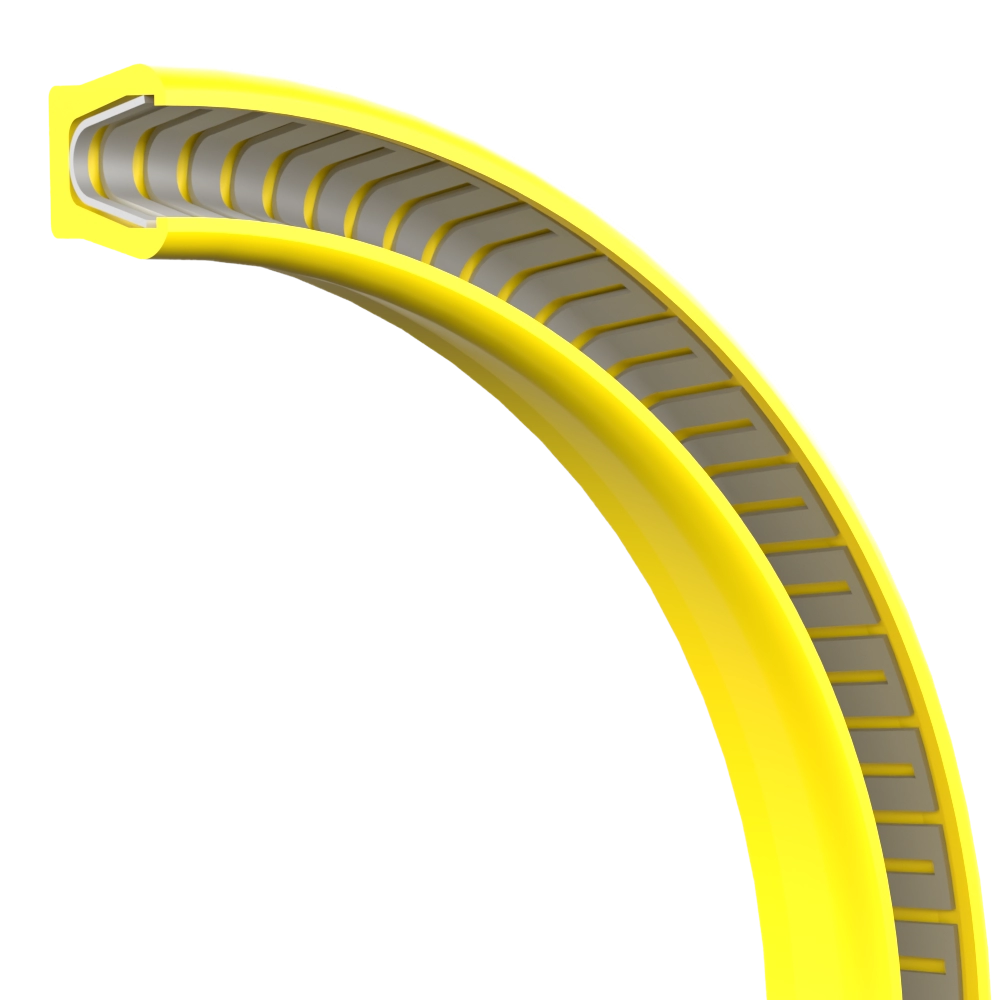

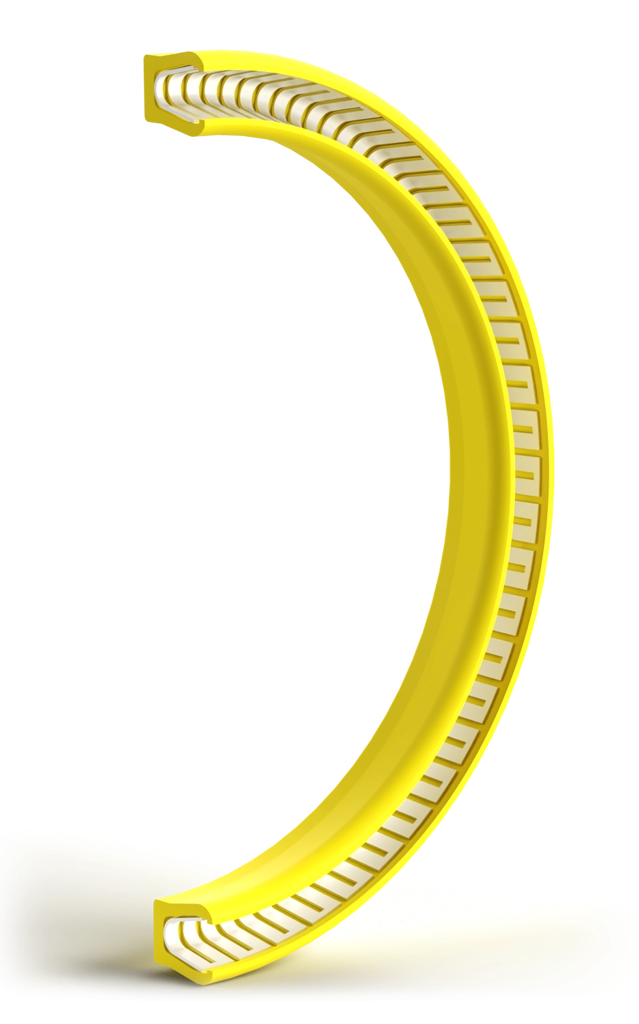

Standard Heel:

Standard

Skived I.D.

Skived O.D.

Inside Face Seal

Outside Face Seal

Extended Heel:

Standard

Skived I.D.

Skived O.D.

Inside Face Seal

Outside Face Seal

Flanged Heel:

Standard

Skived I.D.

Skived O.D.

SEALING APPLICATIONS

High Pressure

.svg)

Reciprocating

Abrasive / Viscous

Rotary

Oscillating

200 SERIES: OPERATING SPECS.

| Gland Cross Sections |

Standard Industrial, Aerospace, and Military glands, plus larger cross-section up to ½” |

| Operating Pressure |

0 to 30,000 PSI and Above |

| Temperature Range |

-40° to 600°F |

| Motion/Speed |

Slow to Medium |

Typical Applications:

- Gear Box Shaft Seals

- Hydraulic/Pneumatic Linear Actuators

- Landing Gears

- Launch Vehicles

- Rocket Engines

- HPHT Low Fugitive Emissions (LFE) Valves

- Adhesive Dispensing Equipment

- Food Processing Pumps

CANTILEVER

SPRING DESIGN FOR OPTIMAL LOAD