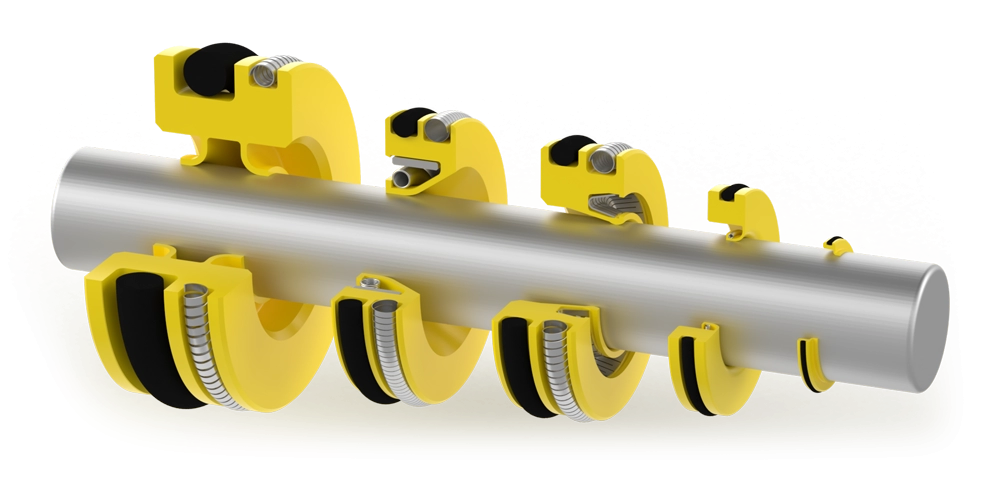

OUR ROTARY LIP SEALS ARE ENGINEERED & DESIGNED TO YOUR APPLICATION REQUIREMENTS

ADVANCED PTFE ROTARY LIP SEAL DESIGN

500 Series PTFE Rotary Lip Seal Features:

- Engineered designs available

- Large diameter capability up to 48”

- Proprietary PTFE-blended seal jackets with superior heat and wear properties

- Extended shelf life

- FDA and USDA compliant materials

- Wide range of spring and O-Ring materials sub “energizers”

500 Series PTFE Rotary Lip Seal Benefits:

- Excellent chemical resistance

- Low friction

- Capable of surface speed in excess of 7,000 ft/min.

- High PV values

- Ease of installation and removal

- Ease of maintenance without damaging the hardware

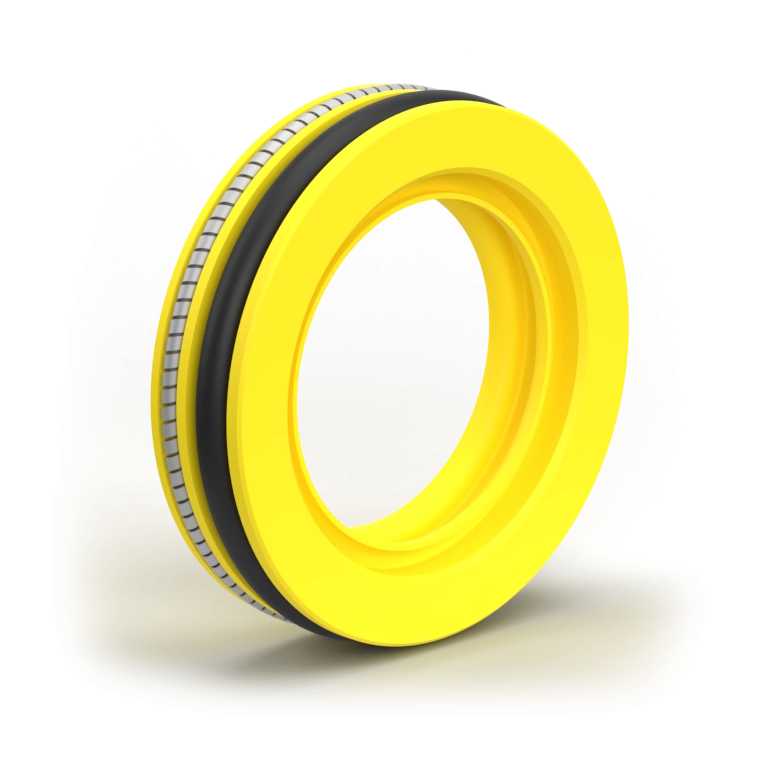

Available Formed Lip Options PTFE Rotary Lip Seals:

.svg)

Double Lip Seal Bi-Directional OD Elastomer with OD Energizer

.svg)

Single Lip Seal with Garter and OD Elastomer

.svg)

Single Lip Seal with OD Elastomer

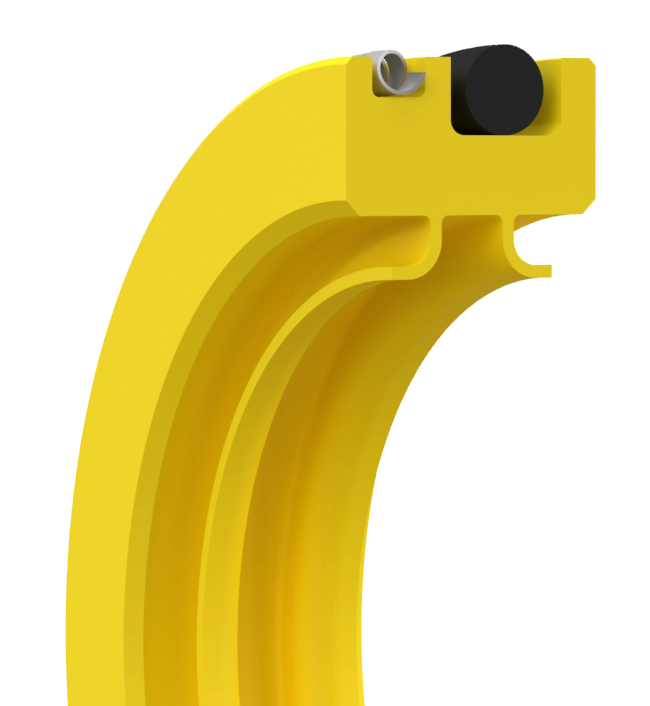

Machined Lip Options for our 500 Series PTFE Rotary Lip Seals:

.svg)

Triple Lip Seal OD Elastomer with OD Energizer

.svg)

Single Lip Seal OD Energizer

.svg)

Single Lip Seal with Garter Spring and Anti-Shrink Ring with OD Energizer and Elastomer

TYPICAL SEALING FUNCTIONS

High Speed

Large Custom Size & Diameter Glands

Lubricated or Dry Running

Abrasive / Viscous

Rotary

Oscillating

ROTARY LIP SEAL OPERATING SPECS.

| Gland Cross Sections |

Custom sizes |

| Operating Pressure |

0 to 500 PSI and above |

| Temperature Range |

-65° to 450°F |

| Motion/Speed |

High speed rotary |

Common Uses for Rotary or Radial Lip Seals:

- Actuators

- Oil and fuel pumps

- High-speed gearboxes

- Turbine engines

- Chemical processing equipment

- Crankshaft and camshaft

- Drilling and tapping spindles

- Electric motors

- Hydraulic motors and pumps

- Mixers

- Pharmaceutical and food processing equipment

- Rotary compressors

- Vacuum pumps

- Medical Handpieces

- Valves

- Break Away Couplers

ENGINEERED

ROTARY LIP SEAL

DESIGNS