CONSTANT SPRING FORCE OVER WIDE DEFLECTION RANGE

ADVANCED SLANT & CANTED COIL SPRING DESIGNS:

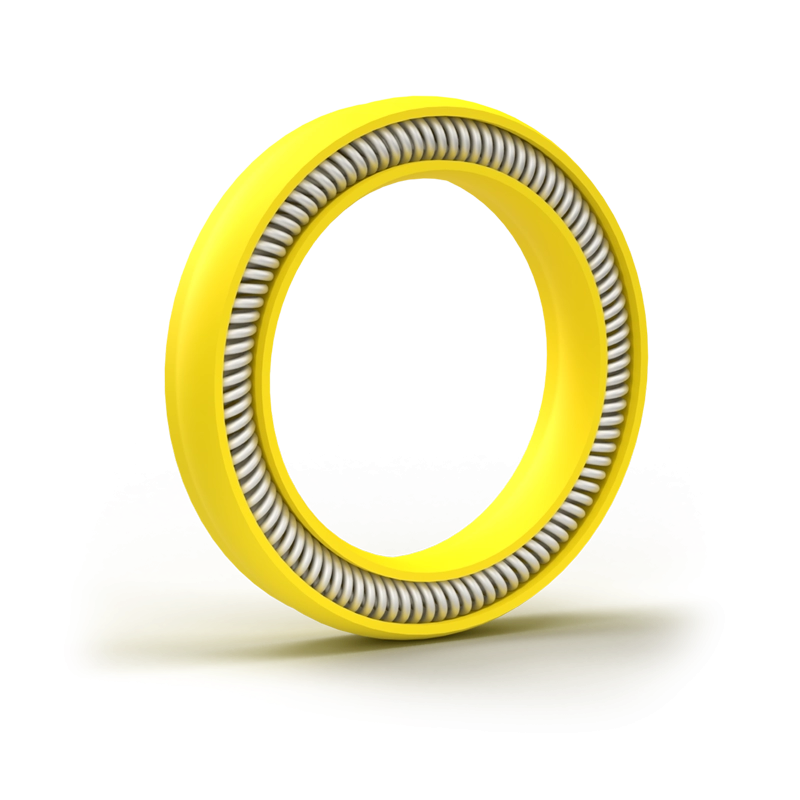

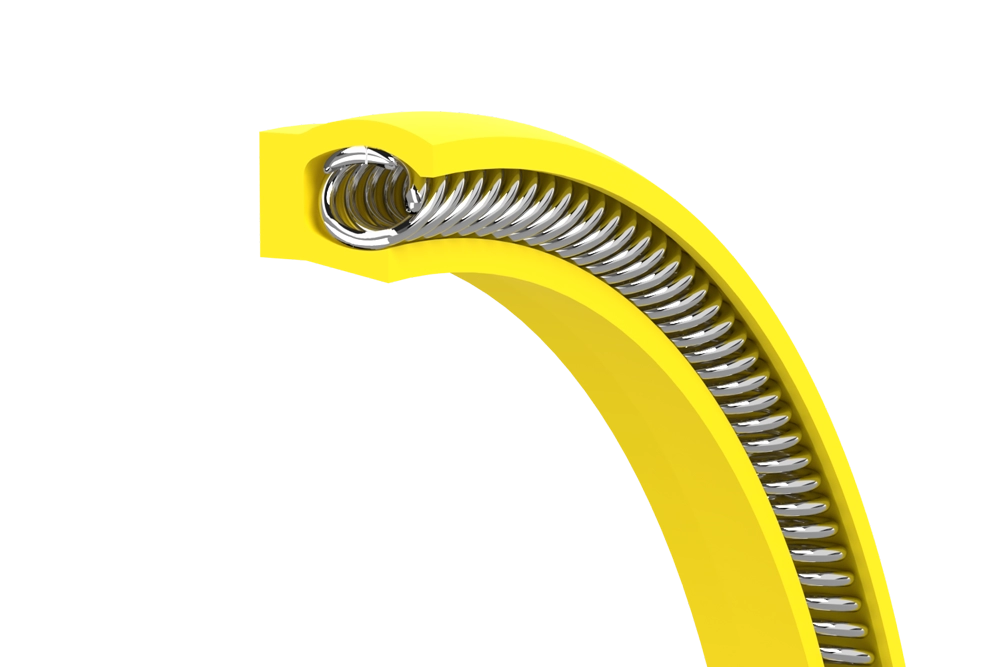

Canted Coil Spring Seal Features:

- Provides unique ‘Force vs. Deflection’ curve upon compression, producing near-constant spring force over a wide working deflection

- Available in three standard spring loads for every gland cross-section

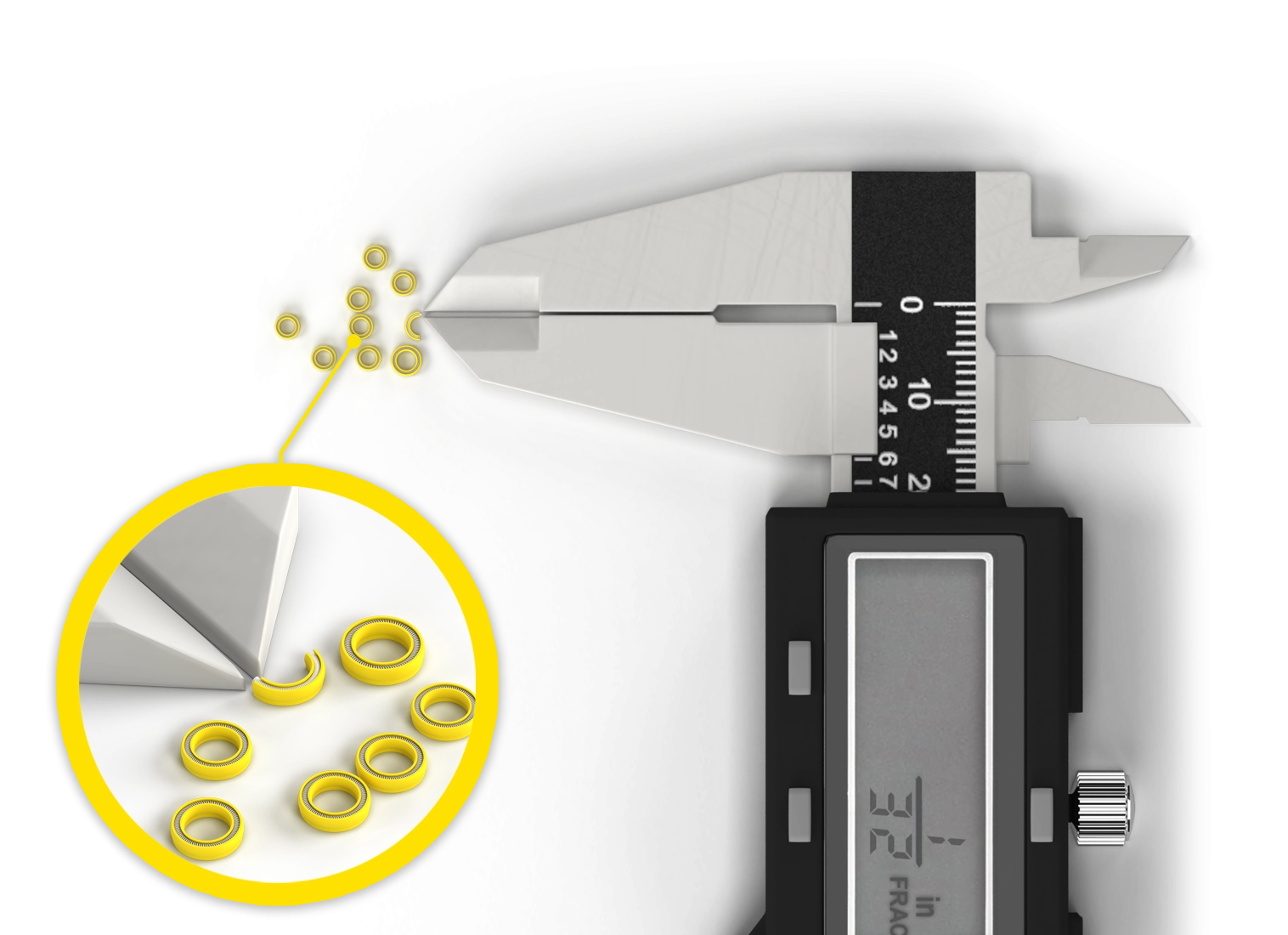

- Cross-sections available are 1/32in up to 1/2in

- Available in all sizes to fit Industrial, Aerospace, and Military glands, with custom sizes ranging from .062” to 48” diameters

- Springs are available in 302 SS, 316 SS, and Hastelloy C276

Canted Coil Spring Seal Benefits:

- Permits wide gland tolerances, misalignment, and surface irregularities.

- Permits large seal wear

- Provides low friction and optimum sealing

- Provides long seal life

- Allows low hardware clamping force

- Can be installed in closed glands with flexible and low stressed slant coil spring

Canted Coil Spring Seals with Standard Heel:

Standard

Skived I.D.

Skived O.D.

Inside Face Seal

Outside Face Seal

Canted Coil Spring Seals with Extended Heel:

Standard

Skived I.D.

Skived O.D.

Inside Face Seal

Outside Face Seal

Canted Coil Spring Seals with Flanged Heel:

Standard

Skived I.D.

Skived O.D.

CANTED COIL SPRING SEALING APPLICATIONS

Micro Sizes

.svg)

Reciprocating

Viscous

Rotary

Oscillating

High Pressure Dynamic

SLANT COIL SEAL OPERATING SPECS.

| Gland Cross Sections |

1/32" to 1/2" |

| Operating Pressure |

0 to 30,000 PSI and above |

| Temperature Range |

-450°F to 600°F |

| Motion/Speed |

Medium to High |

Typical Applications for Slant Coil Spring Seals:

- Medium to high-speed dynamic applications

- Variable gland cross-section with wide gland tolerances

- HPLC and UHPLC applications

- Encoders and flap actuators

- Surgical bone saw

- Battery operated devices

- High-speed medical handpiece

AVAILABLE IN 1/32in GLAND CROSS-SECTION