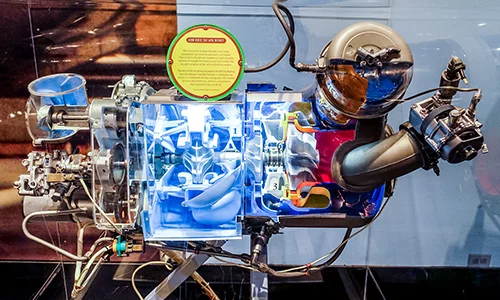

We engineer, design, and manufacture high-performance seals and components for demanding Aviation applications. Polymer Concepts has been an Aircraft Component partner for more than 25 years supplying seals for a variety of Commercial, Government, and Military applications. Our Spring-Energized Seals and Rotary Lip seals, utilizing our extensive Material Polycon Library, can be found in the assemblies of Passenger Aircraft, Helicopters, and Defense Platforms.

We recognize the special operating requirements as set forth by our Aviation partners and have developed critical components that reduce maintenance time, increase operating cycles before needed replacement, help improve the overall safety of the operators and passengers aboard, increase cost savings per part and promote overall efficiency of our client's applications.

Seal design is a complex process, especially in aviation applications where certifications and rigorous zero-failure standards are a must to ensure that flight operations go smoothly and without catastrophic failure. We help you navigate those challenges with extensive hardware consulting, operations testing, seal qualifications, and customized seal cross-section design to meet your application requirements.

Polymer Concepts’ Aircraft Seal and Component Advantages

Maintenance-Free Solutions

Low Friction Materials

High Pressure Sealing

Lightweight Components

Excellent Chemical Resistances

High/Low Temperature Resistances

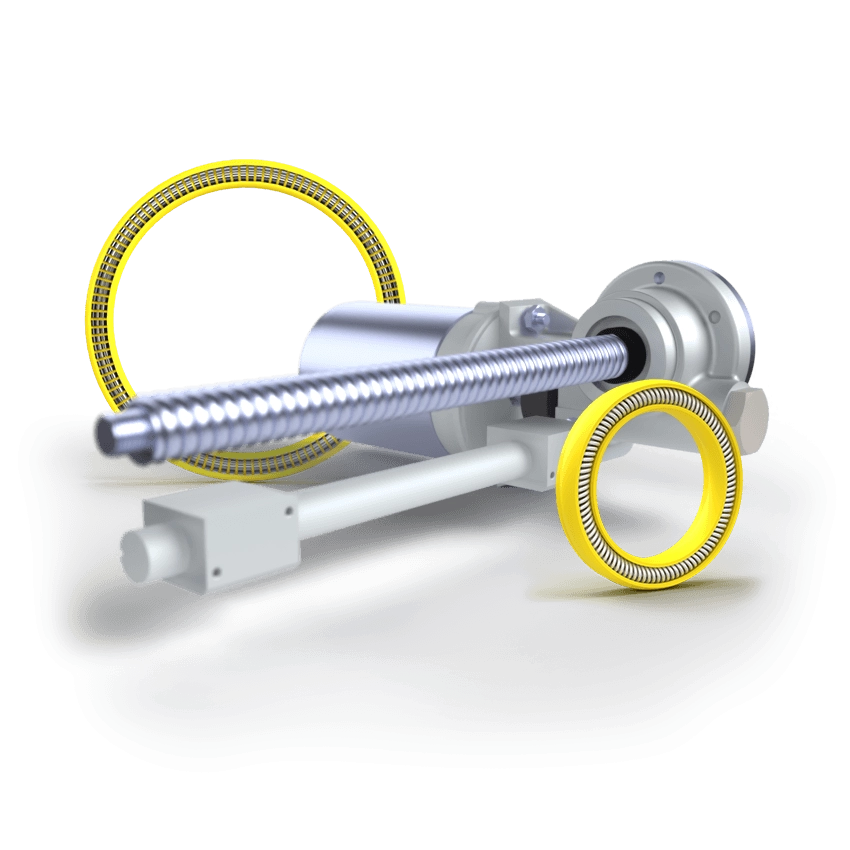

Aircraft Seal and Component Designs

100 SERIES DESIGN - LEARN MORE ABOUT THIS SERIES

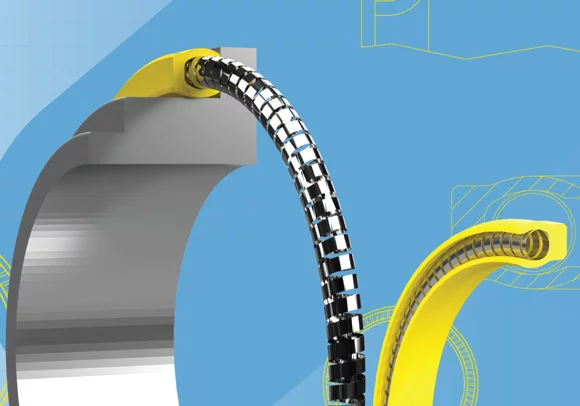

ADVANCED HELICAL SPRING SEALS (AHS)

- Utilized in Cryogenic and High Pressure Environments

- Great for Fuel Tanks and HVAC Systems

- High Load Characteristics

- Utilized in Static and Slow Dynamic Applications

- Bleed Air Valves, Anti-Icing Systems

200 SERIES DESIGN - LEARN MORE ABOUT THIS SERIES

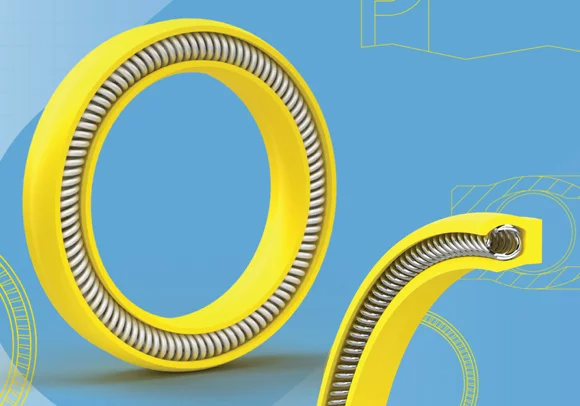

ADVANCED V-SPRING SEAL (AVS)

- Utilized in Landing Gears and Actuators

- Suitable for Dynamic Applications (Rotary, Oscillating)

- Great for Pumps and Compressors

- Lubrication Systems, Accessory Gearboxes, Turbines

600 SERIES DESIGN - LEARN MORE ABOUT THIS SERIES

ADVANCED SLANT COIL SPRING SEALS (ACS)

- Low Friction Low Spring Load

- As the seal wears, the flat load curve of the slant coil design will remain the same over the life of the seal.

- Low hardware clamping force

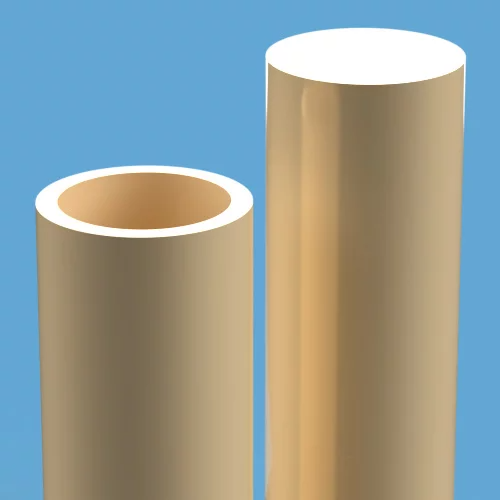

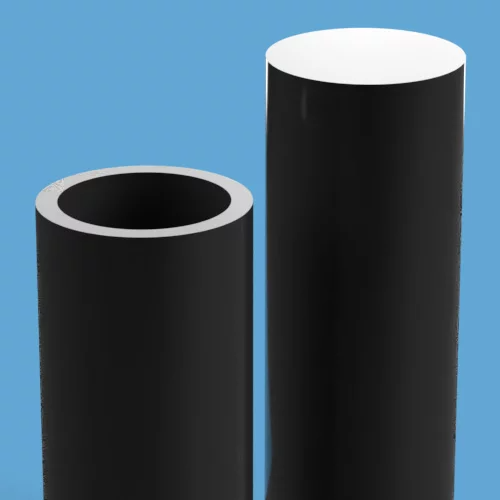

Specialized Materials for Aircraft Seals and Components

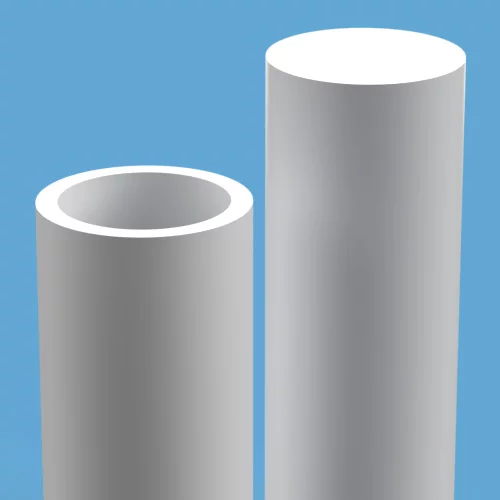

POLYCON 01

Versatile Material, High/Low Temperature tolerances and low coefficient of friction. Low Dielectric Constant and inflammability.

POLYCON 12 and 12D

Better wear resistance than PolyCon 01 with slightly higher coefficients of friction.

Typically used in rotary and reciprocating applications to seal against stainless steel, chrome plated components and aluminum alloys and/or ceramic coatings.

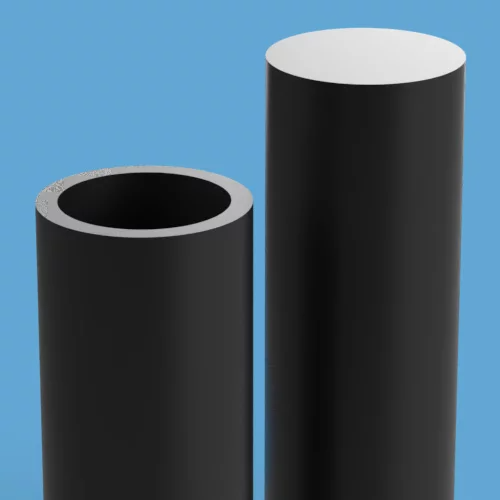

POLYCON 25

Very High coefficient of friction, typically used in bearings, back up rings and bushings. Suitable as a metal alloy replacement.

Material advantages in chemical resistance and ability to withstand aggressive compounds and environments. Excellent electrical insulation properties as well.

POLYCON 25 VARIANTS

Polycon 25 Variants are typically filled custom blends of Polycon 25 and other materials to meet the specific operating requirements of the application.

These additional materials can improve wear resistant, reduce friction, and even alter the thermal properties of the seal.

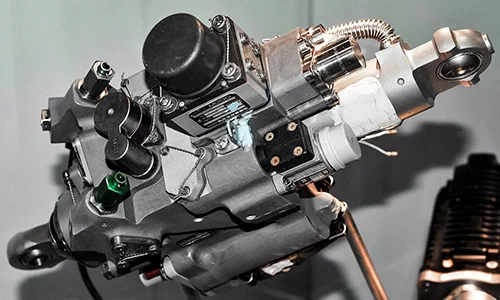

Typical Aircraft Sealing and Component Applications

Aircraft Actuators

APU (Auxiliary Power Units)

Landing Gear Systems

Turbo Shaft and Turbo Fan Jet Engines

AVIATION & AIRCRAFT CUSTOM SEALING SOLUTIONS

THE INDUSTRY-LEADING AIRCRAFT & AVIATION SEAL MANUFACTURER

Polymer Concepts Technologiesdesigns, engineers and manufactures state-of-the-art application-specific sealing solutions and high-performance polymer and fluoropolymer components. We take a collaborative technical approach with our customers and incorporate flexible designs, a vast material portfolio, and experienced manufacturing methodology to tackle the challenges of the most difficult applications. Our in-depth engineering experience, understanding of material characteristics, flexible service, rapid prototyping, and strong Total Quality Management System (AS9100D & ISO9001:2015) ensure an industry-leading solution every time.