Case Studies

Successful Solutions for Difficult Sealing Applications

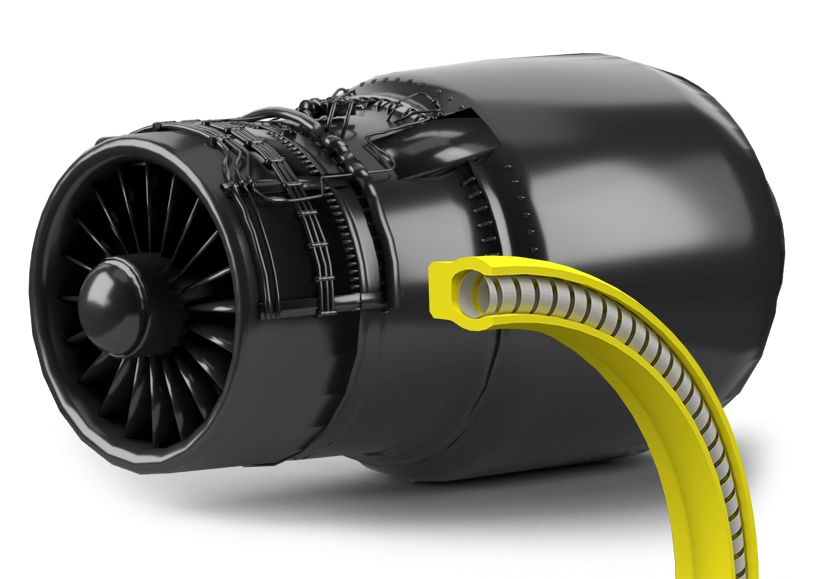

Aerospace

High temperature and critical structural application

Challenge:

Customer required a high temperature PTFE seal design that improved gland fit, decreased seal wear and increased operating life cycle.

Performance Critical Spec.

50°F to 600°F

Media:

Aircraft Exhaust

Solution:

Utilizing our rapid prototyping department, PCTI was able to quickly meet the application design requirements as provided. We worked with our materials partners to develop a unique non-conductive PTFE blend, and our in-house team, to develop an engineered spring energized seal design. Additionally, we designed advanced, low friction, and high load wear rings for use in this application.

Result:

With two weeks of lead time, PCTI was able to meet all of the customer’s design requirements and specs. Our seal design outperformed the in-place sealing solution and achieved qualification certification. The PTFE sealing solution as designed offered a unique solution to the customer's lower wear and longer service life.

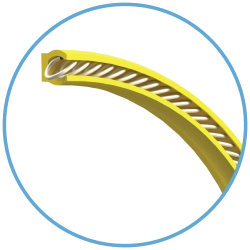

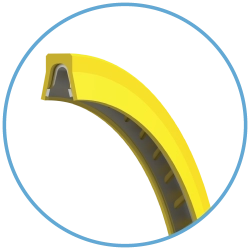

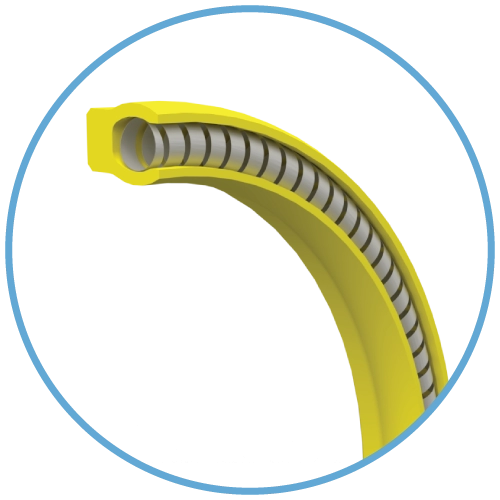

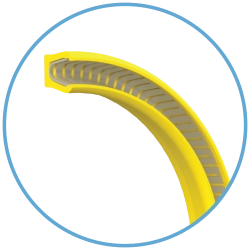

Engineered Jacket Design

Advance PTFE Jacket and Spring design based on our 100 Series: Helical Spring Seal. Modified to the application requirements for optimal friction and sealing in high-temperature applications.

Engineered Jacket Design

Advance PTFE Jacket and Spring design based on our 100 Series: Helical Spring Seal. Modified to the application requirements for optimal friction and sealing in high-temperature applications.

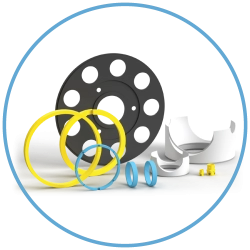

Hardware and Seal Assembly

Designed to your hardware specifications, Polymer Concepts also offers in house hardware design and consulting.

Space Exploration

LOX cryogenic propulsion system seals

Challenge:

Develop a sealing solution operating at Cryogenic temperatures, sealing gaseous media, and under shock and vibration conditions. Performance critical application with zero failure requirements to ensure mission success.

Performance Critical Spec.

-420°F to 200°F

Media:

LOX (Liquid Oxygen)

Solution:

Advance PTFE Jacket and Spring design utilizing our 100 Series: Helical Spring Seals.

Result:

Our modified Helical Spring seal underwent and passed rigorous qualifications testing, and performed successfully during critical mission operation time.

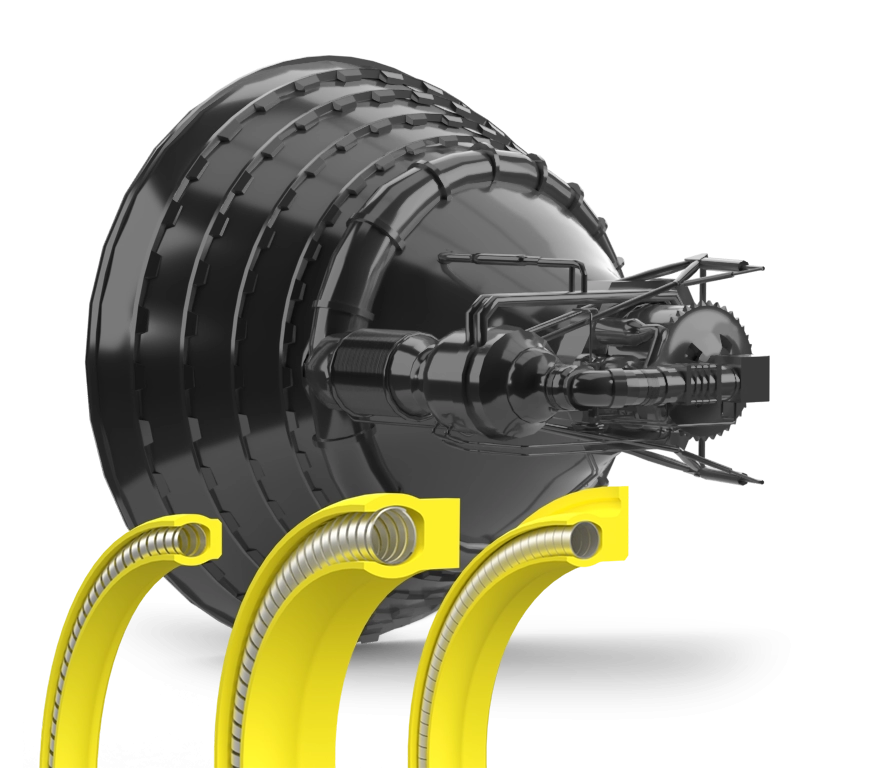

Designed with Cryogenics in Mind

Advance PTFE Jacket and Spring design based on our 100 Series: Helical Spring Seal. Modified to the application requirements for extreme cryogenic temperatures.

Designed with Cryogenics in Mind

Advance PTFE Jacket and Spring design based on our 100 Series: Helical Spring Seal. Modified to the application requirements for extreme cryogenic temperatures.

Medical

High-speed rotary application (equipment to support COVID19)

Challenge:

Develop a unique sealing solution and special compound to perform in high-speed rotary applications, and deliver prototypes within two weeks for validation and rapid delivery.

Performance Critical Spec.

20,000 rpm max

Result:

Utilizing our rapid prototyping department, we were able to supply prototype seals within one week of lead design time. Seals performed to high-speed requirements and supported efforts in the fight against COVID19 and in the manufacturing of Personal Protective Equipment.

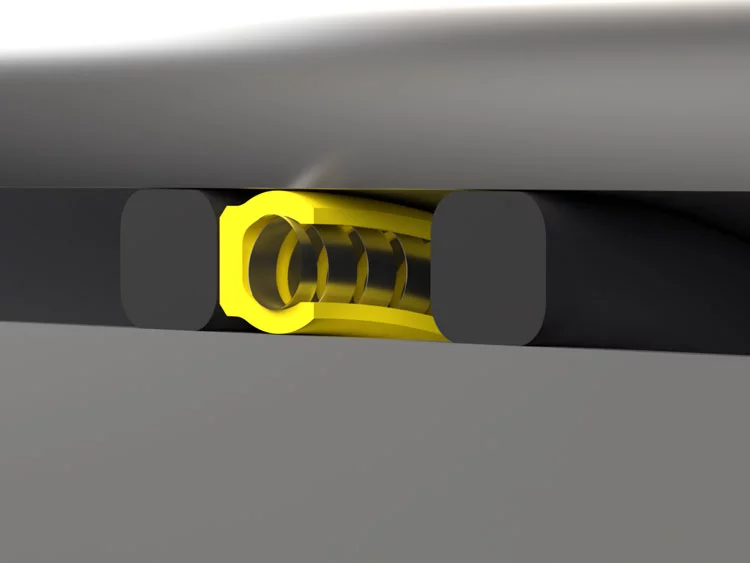

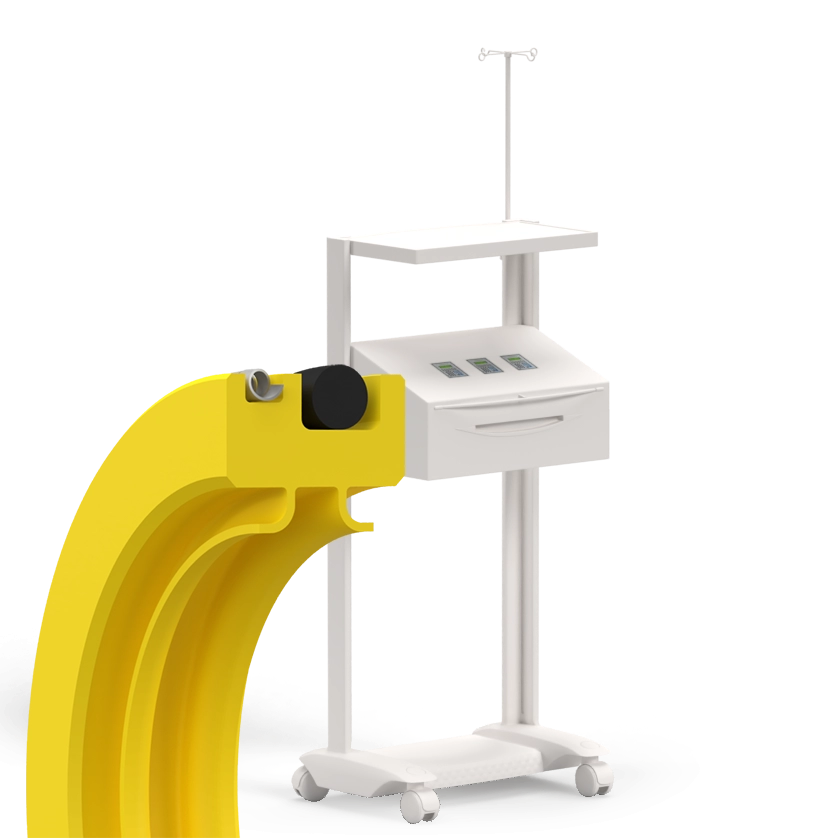

High Speed Rotary Designs

Advance Rotary PTFE Lip Seal design based on our 500 Series: Rotary Lip Seals. Modified to the application requirements for extremely high speeds and nominal operating friction.

High Speed Rotary Designs

Advance Rotary PTFE Lip Seal design based on our 500 Series: Rotary Lip Seals. Modified to the application requirements for extremely high speeds and nominal operating friction.

Military

Thermal Weapons Sight (TWS)

Challenge:

Military contract requirements called for zero leakages, under six feet of water, for a total operating time of five minutes. Our OEM customer required that the thermal sight hardware have minimal friction, to meet the autofocus standards of the application, and to meet MIL-STD-810 environment requirements.

Performance Critical Spec.

Temperature: -25°F to 130°F

Pressure: 1 psi

RPM: Slow Oscillation

Media: Dirty River Water and Open Air

Solution:

Designed and utilized a low spring rate energizer with slant coil skived lip design. The design met minimal surface contact standards, utilizing an in-house low friction graphite filled PTFE compound.

Mission Critical Performance

Advance PTFE Jacket and Spring design based on our 600 Series: Slant Coil Spring Seals. Modified to the customer's requirements for 0 leakage, at 6 ft. of water, for a duration of 5 minutes.

Military Standard Compliance

Mil-STD spec compliance brings to the table a new level of scrutiny and challenges in the seal design and engineering process. With twenty-five years of experience in Military applications, we are no stranger to meeting and exceeding these exacting requirements. We offer many of our products in standard military cross-section sizes.

Mission Critical Performance

Advance PTFE Jacket and Spring design based on our 600 Series: Slant Coil Spring Seals. Modified to the customer's requirements for 0 leakage, at 6 ft. of water, for a duration of 5 minutes.

Military Standard Compliance

Mil-STD spec compliance brings to the table a new level of scrutiny and challenges in the seal design and engineering process. With twenty-five years of experience in Military applications, we are no stranger to meeting and exceeding these exacting requirements. We offer many of our products in standard military cross-section sizes.

Medical

Reciprocating Surgical Instrument

Challenge:

Premature instrument failure of elastomeric seal, attributed to water and medical debris contamination in the device.

Performance Critical Spec.:

Temperature: Autoclave during cleaning and ambient during operation

Motion: 10 cy30 cycles/min stroke .5”

Media:

Autoclave and Medical Debris

Solution:

Engineered 600 Series: Slant Coil Spring Seal with Skived lip via the reciprocating shaft. Utilized FDA compliant materials in the jacket and spring material selection.

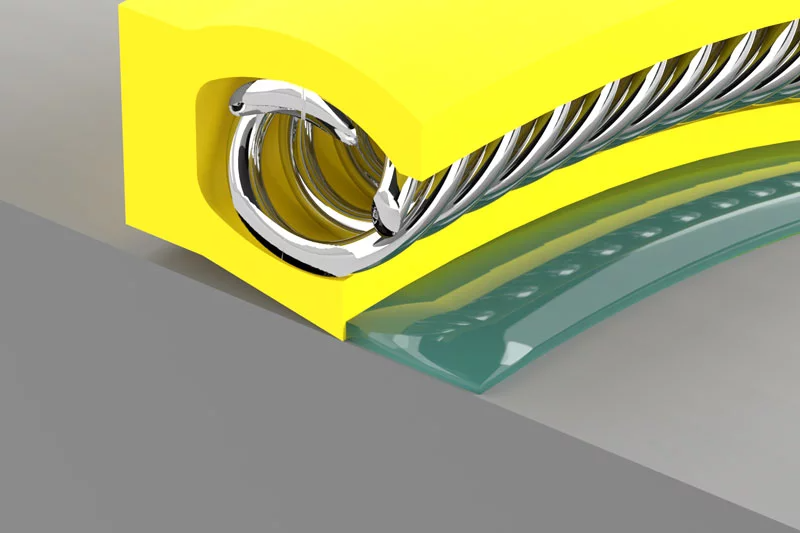

Slant Coil Seal Solution

Advance Rotary PTFE Lip Seal design based on our 600 Series: Slant Coil Spring Seals. Modified to the application requirements, utilizing a Skived lip design to provide scraping decontamination action.

Slant Coil Seal Solution

Advance Rotary PTFE Lip Seal design based on our 600 Series: Slant Coil Spring Seals. Modified to the application requirements, utilizing a Skived lip design to provide scraping decontamination action.

Skived ID Scraper Action

Our Skived ID design prevents the ingress of media fluid and debris on the inside of the reciprocating shaft. The pointed jacket design removes the fluid and debris by utilizing the built-in motion of the reciprocating element.

Industrial

Pharmaceutical Mixing / Agitator Vessels

Challenge:

Vertically mounted motors added potential contamination to the customer’s Pharmaceutical media, via the gearbox and bearings. The anti-contamination seal needed to be FDA compliant and utilize non-shedding properties. Without an advanced solution, the customer was required to replace the seal after each mixing operation.

Performance Critical Spec.

Temperature: Factory Ambient

Pressure: Vacuum to 100 psi

RPM: Variable - Static to 500rpm

Media: Pharmaceutical Compounds

Solution:

Material specific solution, based in a UHMW jacket and a light load Slant Coil Spring. Our seal design was derived from our 600 Series: Slant Coil Spring Seals.

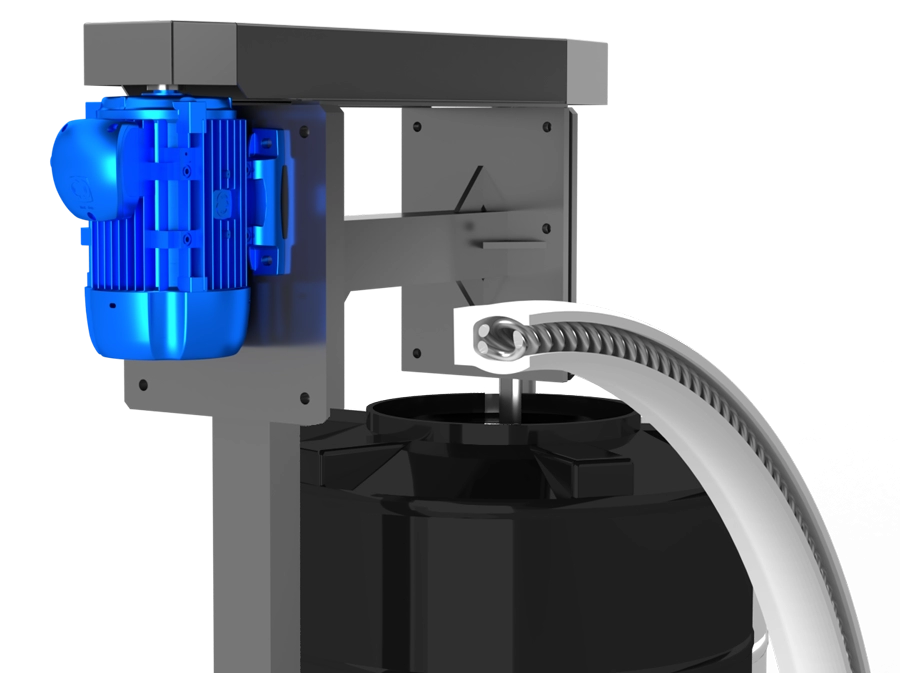

Slant Coil Solution

Advance PTFE Jacket and Spring design based on our 600 Series: Slant Coil Spring Seals. Modified with material selection in mind to meet the customer's FDA requirements.

Protect Your Investment

Our advanced sealing solutions, although small in size, represent an integral part of investment protection and ultimate cost savings.

Our 600 Series Solution, in this application, was able to perform when needed most, stopping the ingress of motor contaminants in the customer's pharmaceutical materials and media.

Slant Coil Solution

Advance PTFE Jacket and Spring design based on our 600 Series: Slant Coil Spring Seals. Modified with material selection in mind to meet the customer's FDA requirements.

Protect Your Investment

Our advanced sealing solutions, although small in size, represent an integral part of investment protection and ultimate cost savings.

Our 600 Series Solution, in this application, was able to perform when needed most, stopping the ingress of motor contaminants in the customer's pharmaceutical materials and media.

Aerospace

Aerospace O2 Regulator for Passenger System

Challenge:

Performance Critical Spec.:

Temperature: Ambient

Pressure: 1800 to 2200 psi

Media: Aviator Grade Breathing O2

Solution:

Engineered 100 Series: Helical Spring Seal utilizing Virgin-PTFE materials and High Rate Helical Sprign Seal.

Helical Spring Seal

Advance Static High Pressure Seal design based on our 100 Series: Helical Spring Seal. Modified to the applications long shelf life parameters

Helical Spring Seal

Advance Static High Pressure Seal design based on our 100 Series: Helical Spring Seal. Modified to the applications long shelf life parameters

Industrial

Hybrid Laser Cutting Optics

Challenge:

Customer was using an o-ring to seal the protective optics from debris and provide force to keep the protective glass in place. Users were having difficulty replacing the glass during maintenance because the o-ring would roll.

Performance Critical Spec.

Temperature: Ambient to 120° F

RPM: Static

Friction Requirement: Low for easy insertion. Ramp style design requirement.

Media: Air and small material debris with indirect contact.

Solution:

External 600 Series: Slant Coil Spring Seal with low spring load rate and graphite filled PTFE material selection.

Slant Coil Solution

Advance PTFE Jacket and Spring design based on our 600 Series: Slant Coil Spring Seals. Utilized an outside face seal approach to improve installation success for the customer.

Slant Coil Solution

Advance PTFE Jacket and Spring design based on our 600 Series: Slant Coil Spring Seals. Utilized an outside face seal approach to improve installation success for the customer.

Semiconductor

Waterproof Servomechanism

Challenge:

The washdown cleaning procedure caused the ingress of water media into the customer’s servomechanism. The sealing solution needed to provide waterproofing at 60psi, 500 RPM, and provide low friction.

Performance Critical Spec.:

Temperature: Ambient to Steam

Pressure: 60 psi

Media: Air, Liquid Water, Cleaning Chemicals and Steam

Solution:

Engineered 600 Series: Slant Coil Spring Seal utilizing skived lip rotary design.

Slant Coil Seal Solution

Advance Rotary Slant Coil Seal design based on our 600 Series: Slant Coil Spring Seals. Modified to the application requirements, utilizing a Skived lip design to provide rotary waterproof seal.

Slant Coil Seal Solution

Advance Rotary Slant Coil Seal design based on our 600 Series: Slant Coil Spring Seals. Modified to the application requirements, utilizing a Skived lip design to provide rotary waterproof seal.

.png)